제품소개

미래를 나아가는 가치의 기술을 실현하는 (주)에이치엠에스코리아

금속시편 전처리장비

- 1. SPECTRAL 250 (Table-top Surface Grinder)

for spectroscopic sample preparation of steels and irons, vibration-free construction, robust steel housing, strong 1.1 kW motor, working disc of 250 mm dia., with rotation speed of 2800 rpm, a rapid stop of the turning disc, suction created by special design retaining the abrasive paper on the disk(no need to glue or fix), disc covered halfway by lid allowing grinding only on a segment, spark trap, dust box and standard outlet for exhauster, easy to clean and ready for operation.

- 2. SPECTRAL 350 (Single/Dual Disc Surface Grinder)

for spectroscopic sample preparation of steels and irons, single disc or two separate independent discs for course and fine grinding possible on 350 mm dia., dynamically balanced, with 2.2 kW driving motor, with rotation speed of 2800 rpm or with dual speeds 1400/2800 rpm., suction created by special design retaining the abrasive paper on the disk(no need to glue or fix), discs covered halfway by lids allowing grinding only on a segment, dedusting system with spark trap and easily replaceable filters, "with interlocking safety switch not allowing the top cover being opened before the motors are stopped, ergonomically designed and "ready for operation. (wooden packing included)

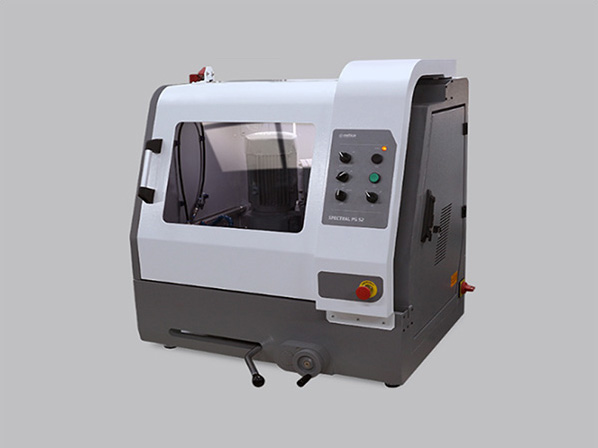

- 3. SPECTRAL PG 52 (Swing Grinding Machine)

for fast spectroscopic sample preparation of iron and steel samples, bench top compact design, closed housing, max. safety provided with interlocking switch, robust column mounted in taper roller bearings, low noise with motor of 3 kW and 2800 rpm, with electronic brake system and overload protection, extraordinary access with sliding door, easy handling with sample swing movement from the front side of the machine, vertical precision positioning of the grinding head with an accuracy of 0.01 mm, large working space with LED lamp, standard outlet for dust exhauster, sample cooling available with water cooling and/or compressed air, complete and ready "for operation. Standard packing included. Without clamping devices. Without cooling tank. 400V, 3-phase, 50 Hz."

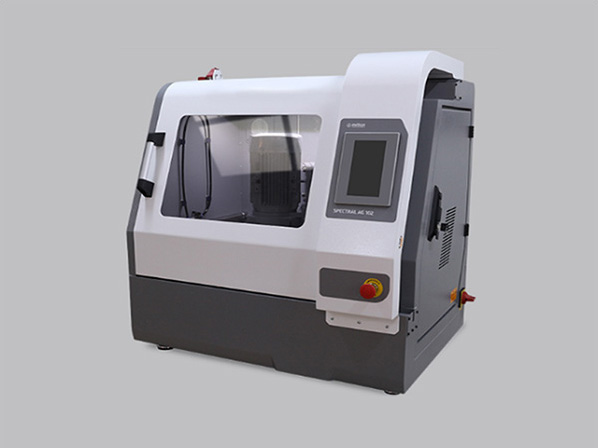

- 4. SPECTRAL AG 102(Automatic Grinding Machine)

for fast spectroscopic sample preparation of iron and steel samples, bench top compact design, Programmable with colored 7'' HMI touch screen control, with Siemens PLC control unit, accurate and motorized positioning in Y and Z axis, closed housing, max. safety provided with interlocking switch, large working space with LED lighting, extraordinary access for easy handling with sliding door, automatic sample feeding with adjustable fine speed, controlled material removal from the specimen with accuracy of 0.01 mm grinding depth, high torque 3 kW grinding motor, with electronic brake system and overload protection, with 2800 rpm speed to obtain optimum surfaces on different materials, all parameters on colored LCD display, sample cooling available with water cooling and/or compressed air, ready for operation. Without clamping devices. Without cooling tank. 400V, 3-phase, 50Hz.

- 1. SPECTRAL 350

- - Suction of paper to the grinding disc which does not require any glue.

- - The equipment is completely closed except for the operating segment to maximize the operator safety.

- - Strong dedusting system with spark trap for dust-free operation.

- - Mechanical & Magnetic Sample Holders.

- 2. SPECTRAL AG 102

- - Sample Height Measurement system for fully automatic cycle.

- - Automatic cup wheel positioning for extremely precise positioning with shorter times.

- - Automatic dressing of the grinding stone.

- - Fully automatic process with sample positioning and cup wheel positioning.

- - Water and air cooling system is available to keep surface temperature at minimum.

- - The table feedrate is designed with the strong positioning motor as 120 mm/sec. to minimize the operation cycle.